Gas Fired Bale Out Furnace

- IMPROVES THE THERMAL EFFICIENCY OF THE MELTING PROCESS

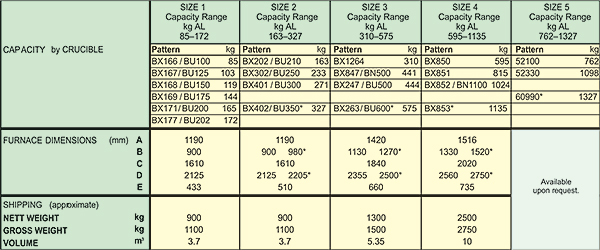

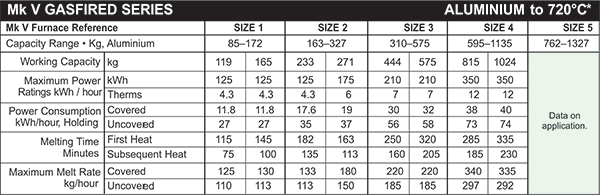

- ALUMINIUM CAPACITIES UP TO 1327 KG

Morgan’s Gas Fired Bale Out Furnace

Furnace Description

The superb insulation allows for excellent melting performance from the high performance compact gas burner. Radiation losses are minimised by use of a well-insulated swing-aside cover that can be sealed when no baling or filling is needed. A low casing temperature provides comfortable working conditionsRADIANT PANEL ASSEMBLIES

Twelve refractory, radiant heater panels are arranged around the crucible and extend to the full depth of the furnace chamber. The self-supporting design facilitates ease of removal in the unlikely event the panels need replacement. These panels efficiently convert gas energy to radiant energy.

HIGH EFFICIENCY

The combination of radiant heat transfer and the use of advanced insulating materials provides a melting and holding furnace of exceptional efficiency and comfortable working conditions.

SIZE RANGE

The furnace is available in sizes ranging up to 1327 kg for melting. Other crucible patterns than those shown in the performance table are available to provide the capacity span indicated for each size reference.

FUELTYPES

Natural Gas: 9000 Kcal/m3

Propane: 22000 Kcal/m3

Butane: 28000 Kcal/m3

Pressure: 20—millibar

PERFORMANCE DATA

*Data for zinc and zinc alloys available one request.

Above data based on optimum foundry conditions. For normal foundry operations a performance of 90% of these ratings is typical.

KEY FEATURES :-

GAS BURNER

The furnace is equipped with an advanced self-contained nozzle

mix gas burner. The burner provides maximum melt rates with

efficient fuel inputs. This maximises crucible life and

performance. The controller and fast response rate of the

furnace nearly eliminate temperature overshoot.

This reliable, fully-modulating industrial grade burner utilises

anultra-violet detector to monitor the presence of combustion.

Accurate ratio control minimises emissions of NOx and CO.

CONTROL PANEL

- Circuit breaker for isolation and protection

- Proportional control gas burner

- Crucible and heater hour meters

- Programmable time clock switching

- Mimic display

- Flame failure, sequencing controller

Metal temperature control may be either from a floating or

fixed pyrometer or one housed within the crucible.

The programmable controller will maintain the metal

temperature within very close limits, by automatic adjustment

to heat input, whether melting or holding.

The digital display shows both the required temperature and

current metal temperature.

TEMPERATURE DEPRESSION

This energy conservation feature enables a lower holding temperature to be automatically selected during periods of non use. A dedicated real-time/date clock can be programmed to select reduced temperature and to return to operational temperature. when required. Similarly, the real-time clock can be programmed to start up and shut down the furnace at preset times and dates.

THERMOCOUPLE FAILURE PROTECTION

If the thermocouple sensor fails, this feature provides a programmed level of output power. Typically set to 10-30%, the time proportioning power control provides sufficient heat output power to maintain an aluminium charge within an acceptable temperature range.

lifespan.

POLICEMAN CONTROL

The furnace is equipped with a ”policeman” control. This feature is designed to prevent overheating of the furnace refractories and radiant panels, thus avoiding reduction of their lifespan.

PYROMETRY

A variety of metal temperature pyrometry can be specified. This Includes floating or fixed immersion types and thermocouples housed within the crucible for holding applications.

OPTIONS AVAILABLE

Spilt metal detection, low metal temperature alarm, in-range indicating beacons, pneumatic swing-aside cover, and metal temperature overshoot control

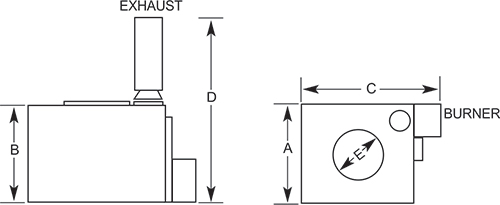

SPECIFICATIONS NOTE: Opposite hand available. *increased furnace height.