Morgan Electric Resistance Bale Out Furnace

A highly efficient crucible bale out furnace for melting and holding with the following advantages:

- Freely radiating elements for imporved performance

- Very low heat loss

- Fast element change

- Low power requirement

- Long element life

- Continuous element monitoring and display for rapid diagnostics

- Aluminium capacities up to 1135 kg.

- Separate element temperature protection

- Half power switching

- Accurate metal temperatures through automatic, proportional, integral and derivative control

- Conforms to the relevant Indian Standards on safety.

Furnace Description

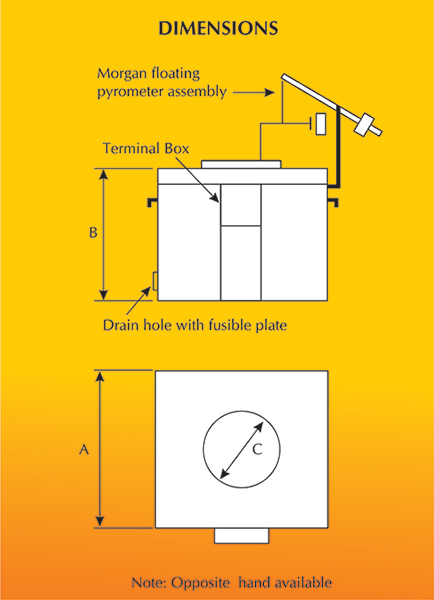

The type HE Furnace is constructed using the most efficient low thermal mass materials for the lining and provides the maximum economy in energy cost.The superb insulation allows for excellent melting performance at high power efficiencies, consistent with long element panel life.

Radiation losses are minimised by use of a well insulated swing aside cover that can be sealed when no baling out is needed.

Heater Assemblies

Twelve refractory heater panels are arranged around the crucible and extend to the full depth of the furnace chamber. Typical power loadings of only 3-4 watts/sq.cm ensure long life. whilst the self-supporting design facilitates ease of removal. multistrand element tails and cool stud terminals enable element changes to be made in less than 10 minutes without removing the crucible.

Control Panel

The control panel provides:

- Circuit breaker for isolation and protection

- Earth leakage detection for operational safety

- Crucible and heater hour meters

- Time clock swithching. The furnace elements are depicted on a mimic diagram and ultra bright LEDs. are lit when any panel is drawing the required current

Metal temperature control may be eighter from floating or fixed pyrometers or one housed within the crucible.

The programmable Controller will maintain the metal temperature within very close limits by automatic adjustment to heat input, whether melting or holding.

The digital display shows both the required temperature and current metal temperature.

Options

Details of optional extras available and furnace variants, ie:

- Larger capacity, low height furnaces for holding applications

- Electronic kilowatt hour meters for kWh totalising or with energy management output and direct kW reading.

- Thyristor control for contactless switching and potential use of energy management systems for multiple furnace installations

- conforms to the latest compatibility standards

Key Features

Improved Temperature Control

Temperature scheduling of control terms provides maximum accuracy of metal temperature whether melting from cold or maintaining.

Temperature Depression

This energy conservation feature enables a lower holding temperature to be automatically selected during periods of ‘ non use’. The controller contains a real-time/date clock, which can be programmed to select reduced temperature and to return to operation temperature when required. Similarly, the real-time clock can be programmed to start up and shut down the furnace at preset times and dates.

Enhanced Power Management

This feature, when selected by the panel mounted switch, reduces output power by 50% at a preset temperature below the normal operating value. output power is therefore limited to half power during holding should the temperature fall outside an acceptable limited due, for instance, to cold metal addition full power is re-established to provide rapid recovery. Half and full power switch positions are also provided.

Output Limited Thermocouple Failure Protection

if the thermocouple sensor fails, this feature provides a programmed level of output power control. Typically set to 10% the time proportioning power control provides sufficient output power to maintain an aluminium charge within an acceptable temperature range.

Improved Top Cover Insulation

The addition of insulation with exceptional insulation properties to the furnace reduces surface temperature, thereby improving working conditions, heat loss safety.

Standards

The Morgan Electric Resistance Bale Out Furnace Type He MkIV has been designed and manufactured in accordance with the relevant national & international Standard.

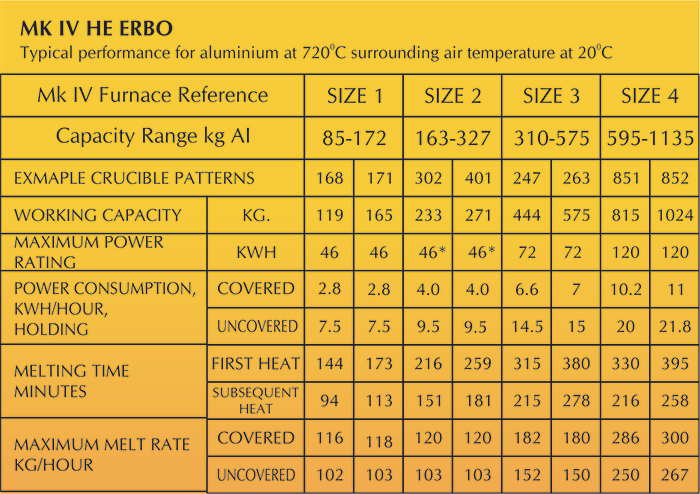

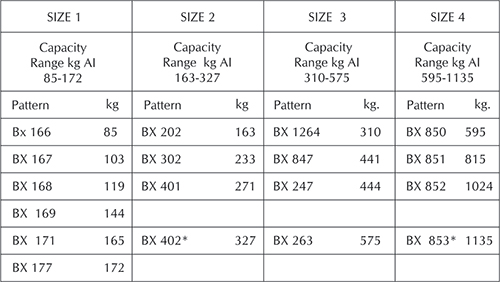

Range

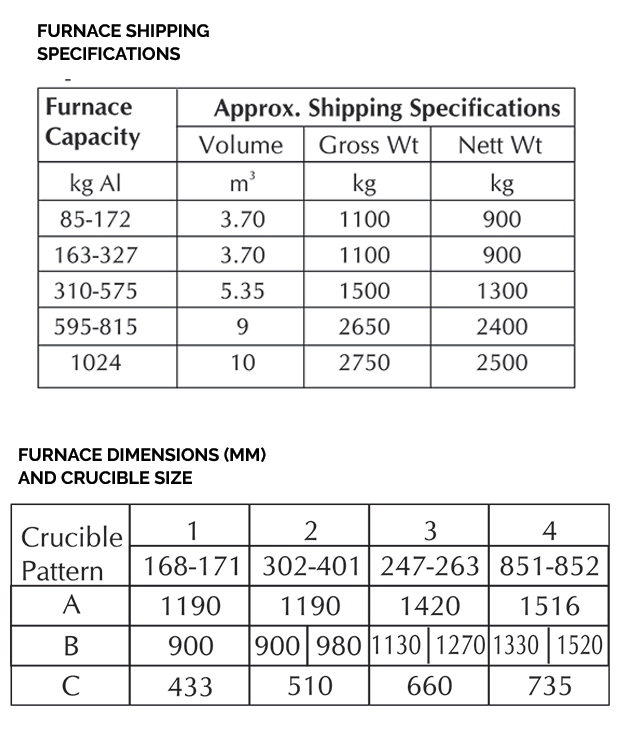

The Morgan Electric Resistance Bale Out Furnace Type HE MkIV is available in the size range 85 kg-1135kg aluminium. high temperature versions available up to 1050 c capacities 260 Kg.-1400 Kg brass. other crucible patterns than those shown in the performance table are available to provide the capacity span

Indicated for each size reference.

zinc and Brass melting data available on request

*Also available at 54Kw

Specifications

Crucibles for Bale Out furnaces

*Increased furnace height

© 2015. «Fuel Furnaces Manufacturers».

All right reserved.

Developed and Designed by Windexinfotech