RECUPERATIVE GAS FIRED BASIN TILTING furnaces

- IMPROVES THE THERMAL EFFICIENCY OF THE MELTING PROCESS

- REDUCES FUEL CONSUMPTION

- LOW NOISE LEVEL

- LOW HOLDING COSTS

- SIMPLE MAINTENANCE

Furnace Description

The steel furnace casing is lined with MorganMMS radiant panels backed by premium grade insulation.LIP AXIS POURING

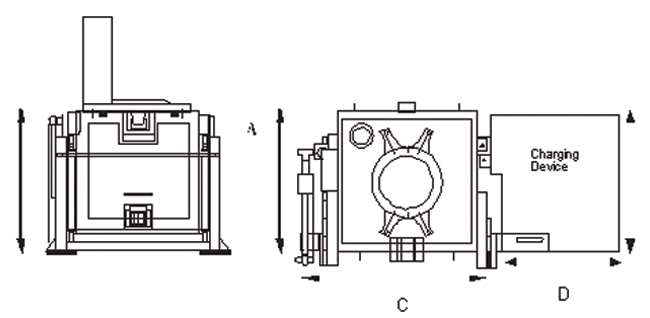

Lip axis pouring is achieved by tilting the furnace by means of twin hydraulic rams. The pouring rate is easily controlled, allowing a transfer ladle to be kept in one position.

SIZE RANGE

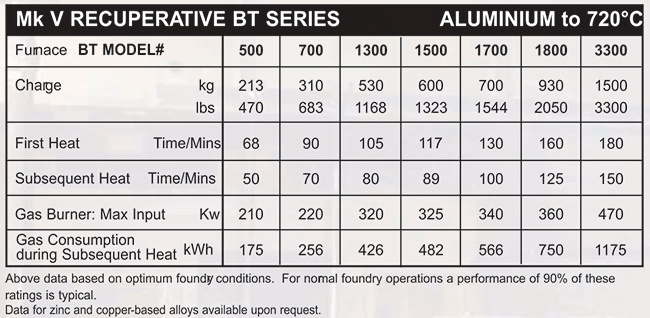

213—1496 kg Aluminium

CONTROL SYSTEM

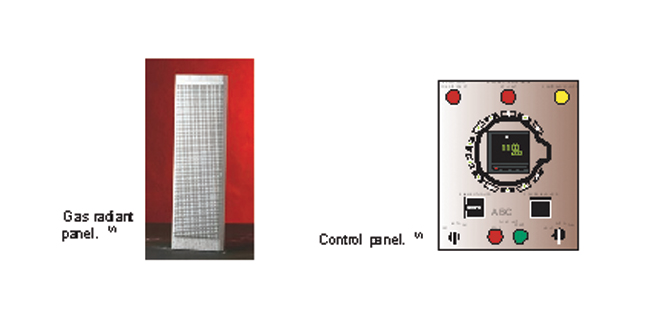

Furnaces with automatic, fully-modulating burners are supplied with a fixed pyrometer assembly, which is connected to the control system, to provide metal temperature control. Other control systems are also available.

INSTALLATION

The furnace is supplied assembled and only requires bolting down on a suitable concrete floor and connection to fuel and electricity sources. For zinc and aluminium melting, MKV Furnaces up to BT700 Furnaces can be fitted with a spilt metal tray. Otherwise, spilt-metal pits should be provided.

PERFORMANCE DATA

KEY FEATURES

BURNER EQUIPMENT

- Fully-Modulating Gas Burners: high velocity, low NOX, pre heated air, nozzle mix, with inverter fan control

- Exhaust recuperator

- Burner Tilts with Furnace

- Radiant Panels

- Crucible and Burner Hour Meters

- Seven Day Time Clock

- Proportional (PID) Control

FURNACE LINING

For aluminium and zinc alloy applications : lined with a high alumina, gas radiant panel hot face, backed with a highly

efficient insulation. The system is particularly beneficial in gasfired applications, providing an effective radiating surface from the non-luminous productions of combustion.

BENEFITS

- Very Low Energy Costs

- Good Metal Temperature Control

- Very Low Casing Temperature

- Low Noise Level

- Low Holding Costs

- Simple Maintenance

The furnace is equipped with a "policeman" control. This feature is designed to prevent overheating of the furnace refractories and radiant panels, thus avoiding reduction of their lifespan.

PYROMETRY

A variety of metal temperature pyrometry can be specified. This includes adjustable or fixed immersion types and thermocouples housed within the crucible for holding applications.

OPTIONS AVAILABLE

Spilt metal detection, low metal temperature alarm, in-range indicating beacons and metal temperature overshoot control.

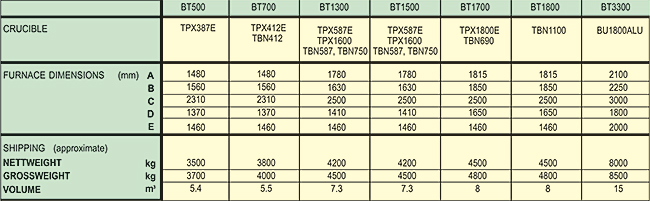

SPECIFICATIONS

© 2015. «Fuel Furnaces Manufacturers».

All right reserved.

Developed and Designed by Windexinfotech